How Machines Play a Crucial Role in Automobile Manufacturing Introduction...

Read MoreHow Machines Play a Crucial Role in Automobile Manufacturing

How Machines Play a Crucial Role in Automobile Manufacturing

Introduction

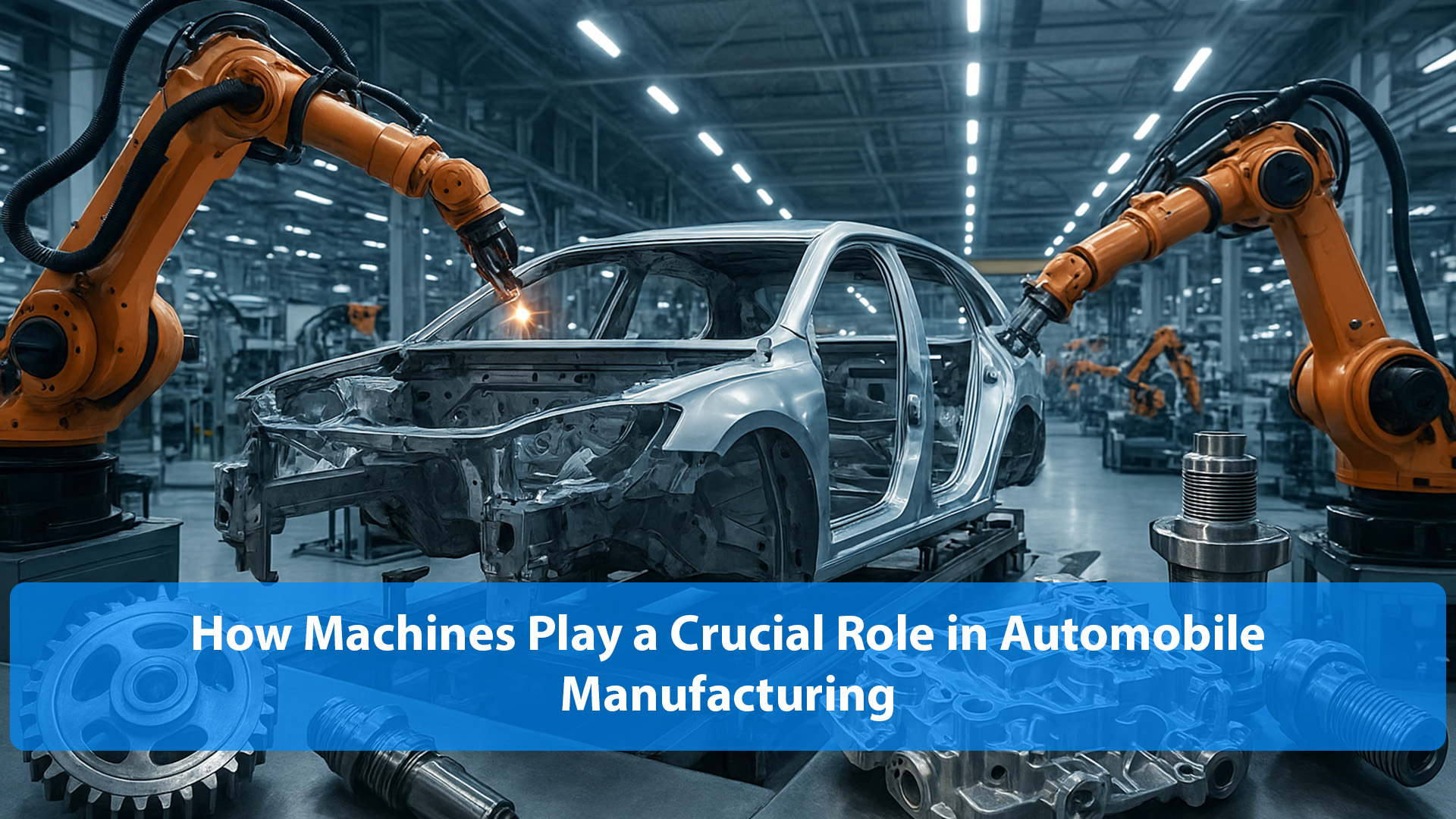

The automobile industry has evolved into one of the most technologically advanced sectors in the world. At the heart of this evolution lies machinery — the silent powerhouse that ensures speed, precision, safety, and efficiency. From cutting metal sheets to assembling entire vehicles, machines have revolutionized how cars are built.

At Micro Engineers, we understand the importance of advanced machinery in creating reliable and high-performing automobile components. Let’s explore how machines have transformed automobile manufacturing into a highly efficient and innovative process.

1. Precision and Accuracy

Modern automobile manufacturing demands components that fit perfectly and function flawlessly. Machines such as CNC (Computer Numerical Control) systems, laser cutters, and automated drills ensure millimeter-level precision.

This accuracy not only enhances vehicle performance but also improves safety and durability.

Example: CNC machines create engine parts and gear systems with extreme accuracy, reducing the risk of mechanical failure.

2. Speed and Efficiency

Gone are the days when car production took months. Today’s automated machines can perform complex tasks in seconds — from welding car bodies to painting exteriors.

Robotic arms, conveyor systems, and automated assembly lines work together to increase productivity while minimizing human fatigue and errors.

With automation, top manufacturers can produce hundreds of cars per day — a feat impossible with manual labor alone.

3. Consistency and Quality Control

Machines are not affected by human limitations like fatigue or mood. This ensures consistent quality output across every vehicle.

Automated inspection systems, equipped with sensors and AI-powered cameras, can instantly detect defects or irregularities, ensuring only the best components make it to the final assembly line.

Quality control machines are key in maintaining brand reputation and customer trust.

4. Safety and Ergonomics

Automation doesn’t just boost production — it enhances safety too. Machines handle heavy lifting, high-temperature operations, and hazardous tasks, keeping human workers safe from accidents and fatigue.

Robotics and mechanized systems are designed to create safer, cleaner, and more ergonomic work environments.

5. Cost Reduction and Sustainability

Though machinery requires initial investment, it leads to significant cost savings over time. Reduced labor costs, less material wastage, and faster production cycles improve profitability.

Additionally, eco-friendly machines with energy-efficient technologies contribute to sustainable manufacturing, aligning with global green initiatives.

Conclusion

Machines are the backbone of modern automobile manufacturing — enabling precision, speed, safety, and sustainability.

As technology continues to advance, the synergy between humans and machines will only grow stronger, paving the way for smarter, more efficient, and eco-friendly automotive solutions.

At Micro Engineers, we integrate advanced machinery and expert craftsmanship to deliver top-quality automobile parts and manufacturing solutions that drive progress and performance.